When embarking on a sheet metal design project, numerous factors determine the final product's performance.

Understanding these considerations initially is paramount to achieving a robust and cost-effective solution. Material selection plays a vital role, considering properties like strength and formability. The shape of the design should be optimized for both application and manufacturability.

Thorough planning to detail in areas like bend allowances, hole locations, and flanges is crucial for seamless fabrication. Furthermore, designing for ease of assembly and possible maintenance can significantly impact the long-term success of the sheet metal component.

Accurate Fabrication of Sheet Metal Components

Sheet metal fabrication is/represents/encompasses a vital process in numerous industries. It involves/engages/demands the manipulation and shaping of thin metal sheets into complex components for a range/various/diverse applications. Precision fabrication, specifically/particularly/especially, plays a critical role in ensuring/guaranteeing/providing the accuracy, durability/strength/robustness, and dimensional integrity of these components.

Modern/Cutting-edge/Advanced manufacturing techniques, such as laser cutting, waterjet cutting, and CNC machining, enable/facilitate/permit fabricators to achieve exceptional levels of precision. These technologies allow/permit/enable the creation of intricate designs and tight tolerances, resulting in high-quality sheet metal components that meet/fulfill/satisfy stringent industry standards.

The benefits of precision fabrication are widely/extensively/abundantly recognized across various/diverse/numerous sectors, including aerospace, automotive, electronics, and construction. Highly/Precisely/Meticulously fabricated sheet metal components contribute to the overall performance/efficiency/reliability and longevity of products in these industries.

Classes and Applications of Sheet Metal Parts

Sheet metal parts are widespread components in a vast range of industries. From simple supports to complex enclosures, these fabricated pieces offer immense versatility. Their fabrication involves cutting, bending, and shaping flat sheets of metal into desired configurations. Typically used metals include steel, aluminum, copper, and brass, each chosen based on its characteristics and the specific needs of the application.

- Applications can range from simple fixtures in automotive manufacturing to intricate elements in aerospace engineering.

- Instances include: sheets for building construction, heat sinks for electronics, and casings for appliances.

The ability to create complex shapes and intricate designs from sheet metal makes it a vital material in modern manufacturing.

Sheet Metal Forming Processes Explained

Sheet metal forming processes alter thin metal sheets into desired shapes and components. These processes utilize a variety of techniques to bend the metal, often through pressing, stretching, or rolling. Common sheet metal forming processes feature bending, stamping, deep drawing, spinning, and extrusion. Each process provides unique advantages and is ideal for specific applications depending on the desired shape, material thickness, and production volume.

- Bending involves applying force to a sheet metal blank, causing it to bend along a specific axis.

- Punching uses a die to cut or shape the metal sheet into precise contours or holes.

- Cup Forming pulls a sheet metal blank into a die cavity, forming a three-dimensional object with a cavity.

Understanding these different processes is vital for designers and manufacturers who work with sheet metal components. By carefully selecting the appropriate process, they can optimize the final product's structure, cost-effectiveness, and overall performance.

Quality Control in Sheet Metal Manufacturing

Sheet read more metal manufacturing relies on meticulous quality control to ensure components meet stringent requirements. A robust quality control process embraces a range of methods, from initial raw material evaluation to final product inspection. During the manufacturing process, skilled inspectors utilize specialized tools and gauges to identify potential defects or deviations from acceptable limits.

A comprehensive quality control plan may comprise a variety of steps, such as:

- Visual inspection

- Size assessments

- Material strength analysis

- Coatings verification

By implementing these quality control strategies, sheet metal manufacturers can ensure the production of high-quality components that meet industry standards. Ultimately, this focus on quality leads to enhanced product performance, customer satisfaction, and a strong reputation within the market.

Advantages of Using Sheet Metal in Engineering

Sheet metal possesses several advantages that highly favorable/desirable/preferred for engineers for a wide range of projects. Its formability allows with simple shaping and manufacturing into complex structures. Sheet metal is also compact, minimizing the overall weight of systems. Additionally, its durability makes it resistant to wear and provides reliable performance. The budget-friendliness of sheet metal also adds to its acceptance in engineering.

Because of these attributes, sheet metal continues a popular material choice for countless engineering sectors.

Alana "Honey Boo Boo" Thompson Then & Now!

Alana "Honey Boo Boo" Thompson Then & Now! Daniel Stern Then & Now!

Daniel Stern Then & Now! Loni Anderson Then & Now!

Loni Anderson Then & Now! Susan Dey Then & Now!

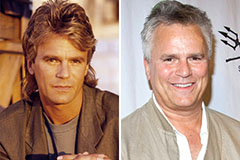

Susan Dey Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!